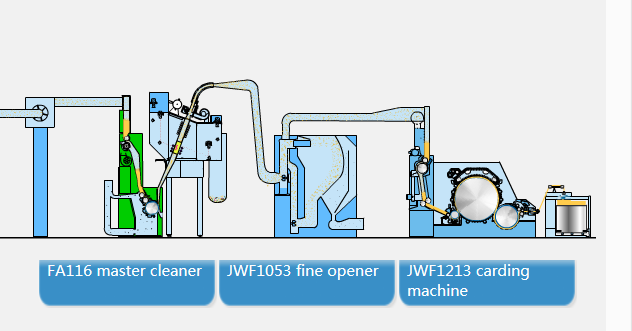

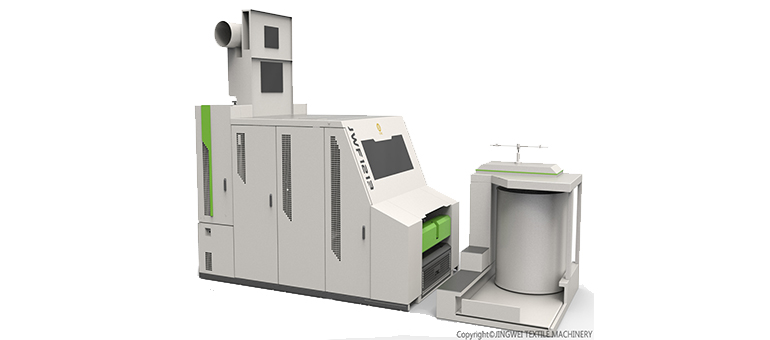

The only manufacture producing three working width carding machine all over the world. New type of chute feeder, with big capacity, supply cotton stably and improves silver evenness and weight regularly efficiently.Air is circling inside the chute feeder, make batt more even and stableHigher Yield, The increase of carding area and the precise carding gauge ensure higher production and better quality; Easy operation and maintenance ,New type flat cleaning and driving system

The step-less speed adjustment ensures the flats cleanness by setting different speeds according to materials; The gauge adjustable design of the brush roller and revolving flats ensures the deep clearing of the revolving flats;The new dust-filtering system adopts the streamline structure and is in more accordance with air motion trail, reducing wind resistance as well as energy and reducing cost;New type of chute feeder, with big capacity, supply cotton stably and improves silver evenness and weight regularly efficiently.Air is circling inside the chute feeder, make batt more even and stable.The New type sealing structure avoids cotton and blocks efficiently

| Basic Information | |

|---|---|

| R & D | 60yrs experience |

| Production | 120,000 frames |

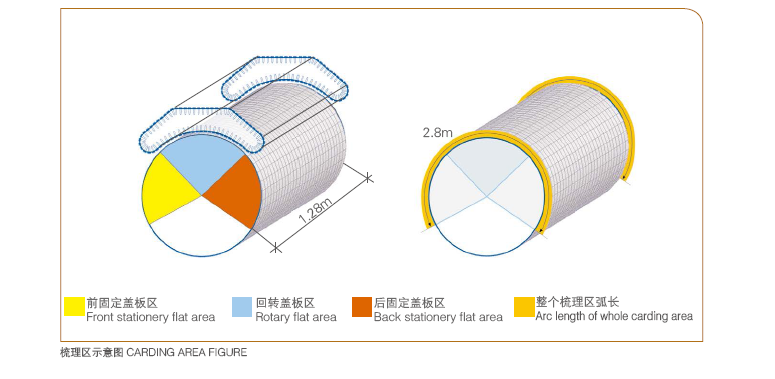

| Width | 1.28m |

| Technical Parameters | |

|---|---|

| Max.output(kg/h) | 160 |

| Sliver count | 3.2~10 |

| Feed weight | 400~1300 |

| Total draft folds | 38~370 |

| Install Power | 3.4KW |

Carding Area

Spinning High Impurity